It is essential to be as efficient as possible to succeed in manufacturing. You need to find ways to reduce waste and speed up production. You have many ways to do this, and some methods are more effective than others. This article will discuss eight ways to make your manufacturing business more efficient.

1. Reduce waste

Waste is an inevitable part of any manufacturing process. However, there are ways to minimize waste and make your production more efficient. You need to ensure that your materials are properly utilized and have a system in place to recycle or reuse any waste products.

Many businesses are moving toward sustainable and “green” practices to reduce waste and save money. They are investing in energy-efficient equipment and using recycled materials. In addition, they are establishing programs to educate employees about waste reduction.

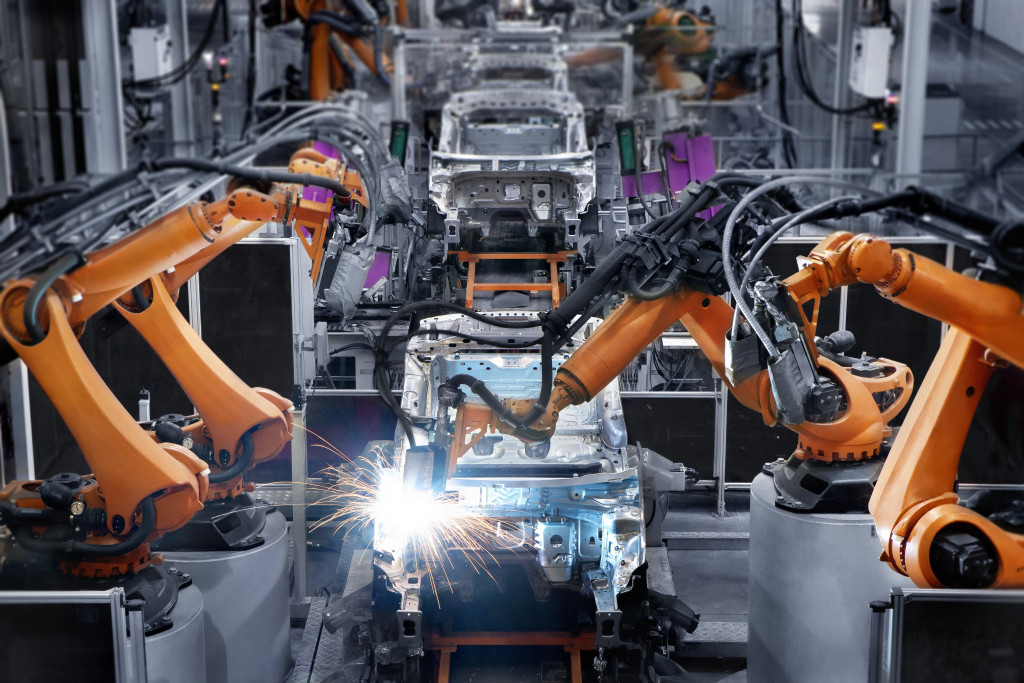

2. Automate repetitive tasks

Manufacturing is often a repetitive process, so automating as many tasks as possible makes sense. This will free up your employees to focus on more important tasks and reduce the chance of human error.

One way to automate is to invest in scanners and sensors. They can track inventory levels, identify defects, and more. You can also use these devices to automate quality control and material handling tasks. Using these in your production line can help to speed up the overall process.

Sensors Incorporated can provide you with the latest technology to help automate your manufacturing process. Visit their website at https://sensorsincorporated.com/.

3. Streamline the manufacturing process

The manufacturing process can often be complex and convoluted. It would be best to streamline it as much as possible to make it more efficient. Many businesses are investing in new technology and software, allowing them to automate tasks, track progress, and manage data more effectively.

In addition, you need to simplify your processes and make them easier to understand. You can develop standard operating procedures (SOPs) and create flowcharts. These tools will help your employees to understand the manufacturing process and carry out tasks more efficiently.

4. Improve communication

It is important to have a good communication system in place to be on the same page. This includes both internal and external communication. All stakeholders need to be kept up-to-date on the latest information to make informed decisions.

To improve communication in your business, you can invest in software that allows you to automate tasks such as sending out updates and alerts. You can also hold regular meetings to ensure everyone is always on the same page. Some businesses also use video conferencing to improve communication between departments or locations.

Communication should be a top priority in your business. By improving communication, you will make your manufacturing process more efficient.

5. Improve quality control

In any manufacturing business, quality control is essential. You need to ensure your products meet the highest standards and are free of defects. You can use many strategies to improve quality control, such as investing in new technology, implementing quality management systems, and training your employees.

Several companies offer software that can help you automate quality control in your business. Some of these companies are MasterControl, EtQ, and IQMS. Depending on your needs, you can choose a software that suits your business.

6. Implement lean manufacturing

Lean manufacturing is a philosophy that focuses on waste reduction and efficiency. The goal is to produce high-quality products with fewer resources. Many businesses are using lean manufacturing principles to improve their efficiency and competitiveness.

Common lean manufacturing strategies include reducing waste, streamlining processes, and improving communication. The core idea is to eliminate anything that does not add value to the product. This includes tasks, activities, and even people.

If you want to implement lean manufacturing in your business, you need to start by identifying waste areas and working to eliminate them.

7. Train your employees

Your employees are your most valuable asset. You need to train them to carry out their tasks efficiently and properly. Training your employees will help them understand the manufacturing process and how they can contribute to its success.

It is essential to provide your employees with both theoretical and practical training. Theoretical training will teach them the basics of the manufacturing process and how to carry out tasks. Practical training will allow them to apply what they have learned in a real-world setting.

To make your manufacturing business more efficient, you need to invest in new technology and software, simplify your processes, improve communication, and implement lean manufacturing. By taking these steps, you will be able to reduce waste, improve quality control, and train your employees to be more efficient.

Always keep in mind that your goal is to produce high-quality products with fewer resources. Implement these tips, and you will be well on your way to a more efficient manufacturing business.